The Untold Story of Hand Warping at innoweave

Before the Weave – There is Warping.

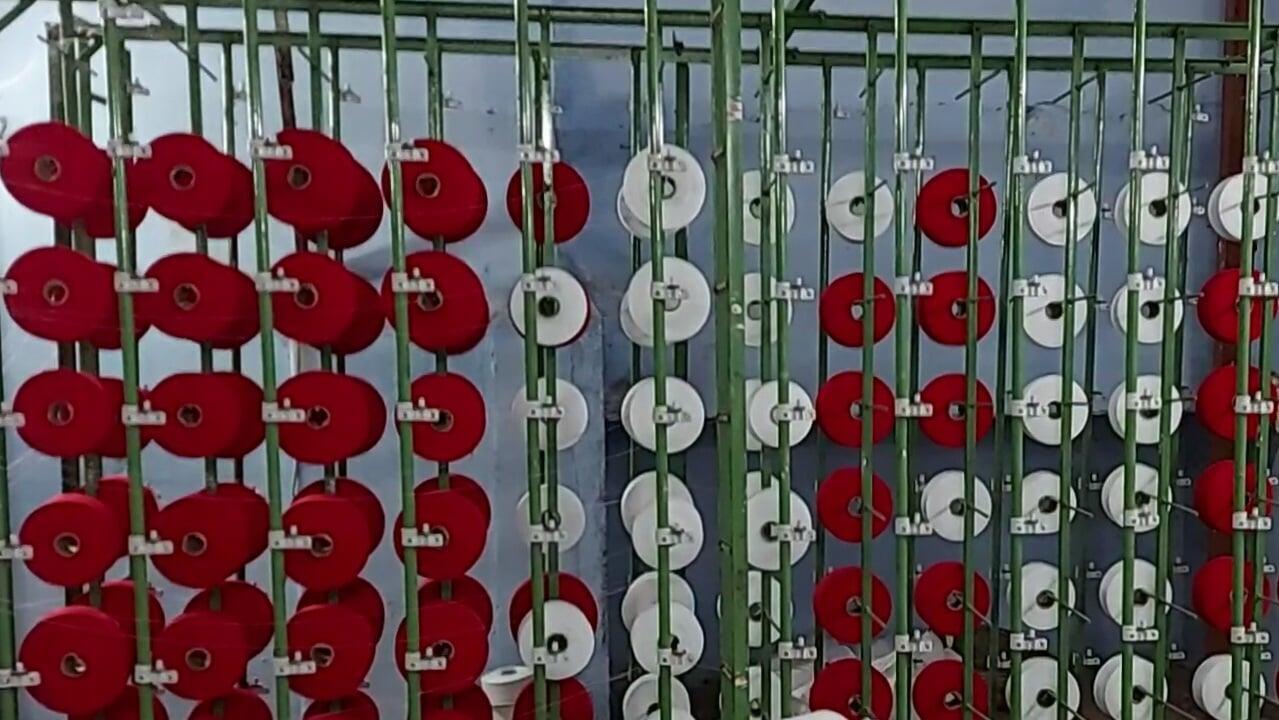

At innoweave, we believe that every thread carries a purpose, and every towel holds a story. But few realise that the story does not begin with weaving. It begins long before, in a quiet corner of our workspace, where a skilled artisan stands in front of a warping drum. This is where hand warping unfolds—a foundational step in weaving that sets the rhythm for everything that follows.

What is Hand Warping?

Hand warping is the methodical process of preparing yarns before they are woven into fabric. The artisan stretches hundreds of yarns across a long warping frame, aligning them with exact length, tension, and order. These yarns are wound carefully onto a warp beam that will later be mounted onto the loom.

It’s slow. It’s repetitive. And it demands precision. But in return, it gives control over the structure, design, and strength of the towel.

At innoweave, we’ve chosen to retain this traditional method not because it is easy, but because it creates depth, durability, and soul in every product we offer.

Why Hand Warping Still Matters Today

In a world rushing toward automation, we pause—because we know some things are worth preserving. Hand warping:

Prevents weaving defects by ensuring perfect yarn alignment

Supports design consistency for patterns and jacquards

Enhances towel durability by maintaining even tension

Honours artisan knowledge passed down through generations

Our commitment is not just to quality but to people—the hands behind the loom, the wisdom behind the process.

The Human Touch Behind Every Thread

Watch closely, and you will notice that no two warping sessions are ever the same. There is a rhythm to the work. A quiet concentration. A dialogue between the artisan and the threads. The yarn is not just pulled—it is measured, aligned, respected.

This is not manufacturing. This is craftsmanship.

At innoweave, each towel reflects that silent dedication. We do not just sell fabric. We bring forward a legacy of textile heritage, where human hands still shape beauty, one thread at a time.

So, the next time you feel the softness of an innoweave towel or admire its durability, know this—it began with a woman, standing before a simple frame, aligning threads with care and pride.

Did You Know?

A single warp setup can involve more than 1,800 yarns, all arranged by hand

Hand warping ensures minimal wastage compared to machine warping.

The technique allows for custom weaving patterns for small-batch, signature collections.